Why Do Stainless Steel Welds Crack . It develops as the chromium oxide layer is destroyed and may. Crater cracks at the end of aluminum welds. Stainless steel tends to be established in a corrosive environment. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Why do stainless steel welds crack? Understanding and identifying welding cracks is vital to maintaining weld integrity. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. Prevention methods are as important as repair strategies. The stress that and the environment that stainless steel is in are. Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas.

from www.youtube.com

Stainless steel tends to be established in a corrosive environment. Understanding and identifying welding cracks is vital to maintaining weld integrity. It develops as the chromium oxide layer is destroyed and may. Prevention methods are as important as repair strategies. Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. Crater cracks at the end of aluminum welds. Why do stainless steel welds crack? Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. The stress that and the environment that stainless steel is in are.

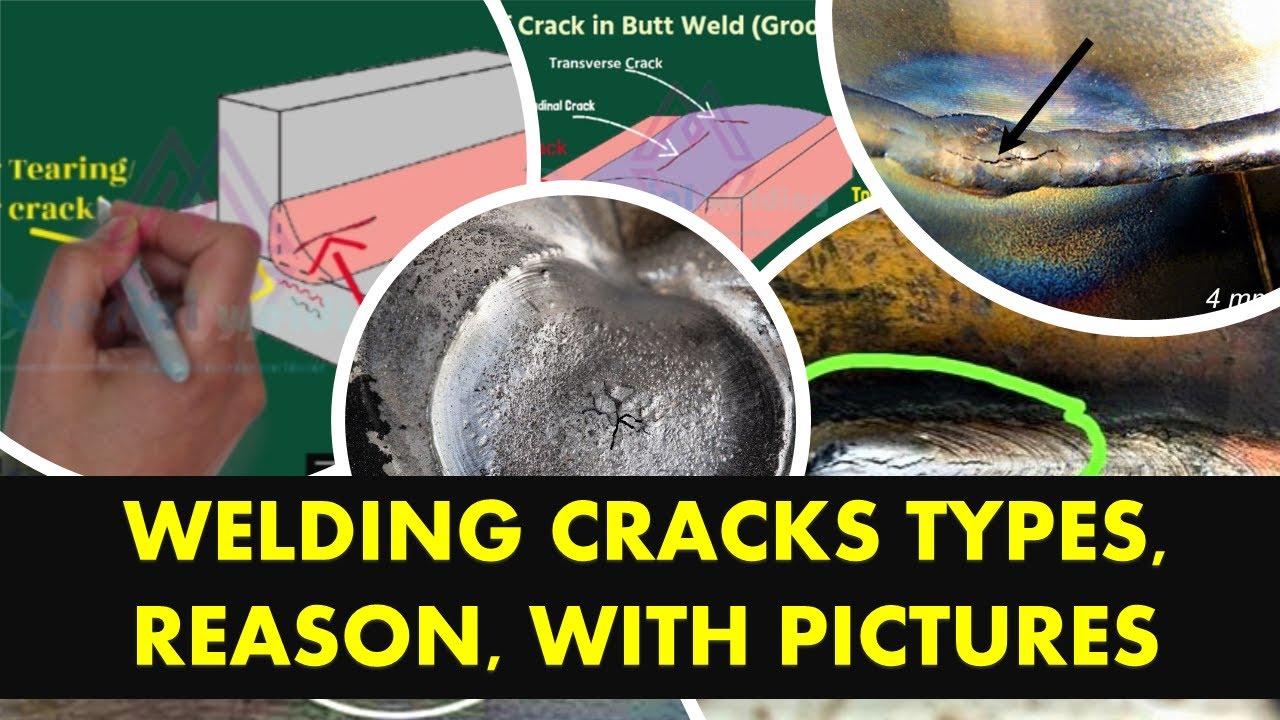

Welding cracks & their types with real pictures YouTube

Why Do Stainless Steel Welds Crack Understanding and identifying welding cracks is vital to maintaining weld integrity. Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. Why do stainless steel welds crack? Prevention methods are as important as repair strategies. Understanding and identifying welding cracks is vital to maintaining weld integrity. The stress that and the environment that stainless steel is in are. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. Crater cracks at the end of aluminum welds. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Stainless steel tends to be established in a corrosive environment. It develops as the chromium oxide layer is destroyed and may.

From www.vrogue.co

What Are Types Of Welding Defects Causes And Remedies vrogue.co Why Do Stainless Steel Welds Crack Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. Stainless steel tends to be established in a corrosive environment. It develops as the chromium oxide layer is destroyed and may. Why do stainless steel welds crack? Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld. Why Do Stainless Steel Welds Crack.

From weldinganswers.com

Understanding Why Your Welds Crack Part I WELDING ANSWERS Why Do Stainless Steel Welds Crack Prevention methods are as important as repair strategies. The stress that and the environment that stainless steel is in are. Understanding and identifying welding cracks is vital to maintaining weld integrity. Stainless steel tends to be established in a corrosive environment. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken. Why Do Stainless Steel Welds Crack.

From blog.thepipingmart.com

What are Welding Defects? ThePipingMart Blog Why Do Stainless Steel Welds Crack Stainless steel tends to be established in a corrosive environment. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Why do stainless steel welds crack? Understanding and identifying welding cracks is vital to maintaining weld integrity. Carbon steel and stainless steel welds are not as susceptible to crater. Why Do Stainless Steel Welds Crack.

From weldingmastermind.com

This Is Why Your TIG Welds Crack (with 3 solutions) Welding Mastermind Why Do Stainless Steel Welds Crack Prevention methods are as important as repair strategies. It develops as the chromium oxide layer is destroyed and may. Why do stainless steel welds crack? Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. Stainless steel tends to be established in a corrosive environment. The stress. Why Do Stainless Steel Welds Crack.

From www.practicalmachinist.com

SS shaft weld repair got crack in surface what to do now? Why Do Stainless Steel Welds Crack The stress that and the environment that stainless steel is in are. Stainless steel tends to be established in a corrosive environment. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. It develops as the chromium oxide layer is destroyed and may. Crater cracks at the. Why Do Stainless Steel Welds Crack.

From weldinganswers.com

6 Mistakes That Can Lead to Cracked Welds WELDING ANSWERS Why Do Stainless Steel Welds Crack Prevention methods are as important as repair strategies. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. The stress that and the environment that stainless steel is in are. Crater cracks at the end of aluminum welds. Stainless steel tends to be established in a corrosive. Why Do Stainless Steel Welds Crack.

From weldguru.com

13 Common Types of Welding Defects & How to Prevent Them Why Do Stainless Steel Welds Crack Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. The stress that and the environment that stainless steel is in are. Crater cracks at the end of aluminum welds. Understanding and identifying welding cracks is vital to maintaining weld integrity. Why do stainless steel welds crack? Stainless steel. Why Do Stainless Steel Welds Crack.

From www.reddit.com

Tig welding stainless steel today r/pics Why Do Stainless Steel Welds Crack It develops as the chromium oxide layer is destroyed and may. Prevention methods are as important as repair strategies. The stress that and the environment that stainless steel is in are. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. Hot cracking often refers to the. Why Do Stainless Steel Welds Crack.

From www.youtube.com

Welding cracks & their types with real pictures YouTube Why Do Stainless Steel Welds Crack Understanding and identifying welding cracks is vital to maintaining weld integrity. Crater cracks at the end of aluminum welds. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in. Why Do Stainless Steel Welds Crack.

From weldinganswers.com

9 Steps to Develop a Repair Welding Procedure WELDING ANSWERS Why Do Stainless Steel Welds Crack Understanding and identifying welding cracks is vital to maintaining weld integrity. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Crater cracks at the end of aluminum welds. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when. Why Do Stainless Steel Welds Crack.

From www.weldingtipsandtricks.com

309 Tig Rod for Welding Stainless to High Strength Steel Why Do Stainless Steel Welds Crack The stress that and the environment that stainless steel is in are. Why do stainless steel welds crack? Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. It develops as the chromium oxide. Why Do Stainless Steel Welds Crack.

From weldguru.com

TIG Welding Stainless Steel A Beginners Guide Weld Guru Why Do Stainless Steel Welds Crack The stress that and the environment that stainless steel is in are. Why do stainless steel welds crack? Crater cracks at the end of aluminum welds. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. It develops as the chromium oxide layer is destroyed and may. Stainless steel. Why Do Stainless Steel Welds Crack.

From www.reddit.com

why is there a crack in the welds? r/Welding Why Do Stainless Steel Welds Crack Why do stainless steel welds crack? Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. The stress that and the environment that stainless steel is. Why Do Stainless Steel Welds Crack.

From www.reddit.com

Why are my stainless steel welds Grey? r/Welding Why Do Stainless Steel Welds Crack Prevention methods are as important as repair strategies. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials. It develops as the chromium oxide layer is destroyed and may. Understanding and identifying welding cracks is vital to maintaining weld integrity. Why do stainless steel welds crack? Stainless. Why Do Stainless Steel Welds Crack.

From www.mdpi.com

Metals Free FullText A Hot Cracking on Dissimilar Metal Weld Why Do Stainless Steel Welds Crack Crater cracks at the end of aluminum welds. Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. It develops as the chromium oxide layer is destroyed and may. Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Prevention methods are as important as repair. Why Do Stainless Steel Welds Crack.

From www.youtube.com

TFS Stainless Crack Repair YouTube Why Do Stainless Steel Welds Crack Prevention methods are as important as repair strategies. Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. Stainless steel tends to be established in a corrosive environment. Why do stainless steel welds crack? Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be taken when welding these materials.. Why Do Stainless Steel Welds Crack.

From www.reddit.com

why is there a crack in the welds? r/Welding Why Do Stainless Steel Welds Crack Hot cracking often refers to the appearance of liquid films along grain boundaries or to another place in the weld metal. Stainless steel tends to be established in a corrosive environment. Understanding and identifying welding cracks is vital to maintaining weld integrity. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be. Why Do Stainless Steel Welds Crack.

From amarineblog.com

Weld Hot Crack vs Cold Crack AMARINE Why Do Stainless Steel Welds Crack Why do stainless steel welds crack? The stress that and the environment that stainless steel is in are. It develops as the chromium oxide layer is destroyed and may. Stainless steel welds produce toxic fumes in the form of hexavalent chromium gas. Carbon steel and stainless steel welds are not as susceptible to crater cracks, but care must still be. Why Do Stainless Steel Welds Crack.